Automatic Dosing on a Programmed Schedule

The Econ T provides a 24-event control capability with an integral timer in a compact pump for light duty applications requiring a dosing schedule.

Applications

- Enzyme injection in drain line in commercial kitchens to avoid costly visits from grease trap clearing companies.

- Biocide feed for Legionella prevention in small cooling towers

- Sanitation for water fountains

- Injection of liquid solar blankets or enzymes in swimming pools

Applications in livestock or poultry water treatment include:

- Continuous delivery of live vaccines; no water consumption calculations necessary.

- Scheduled injection for scale and algae control for evaporative of cool cells.

- Repeatable chemical dosing for effective poultry hatchery dip tank disinfection

How It Works

There are 24 independent programmable on and off events within a 7-day period. The minimum is 1 minute up to a maximum of 23 hours and 59 minutes within each programmed event. Each event can be programmed for a specific ON time and a specific OFF time in increments by hour and minute. The control panel with an LCD display has a programmable clock using a 24-hour format and a battery backup to maintain the internal time and programmed event settings. The display indicators represent the days of the week, operating mode and the events. During operation, the panel displays the current day, time and mode of operation. The pump is also offered in 24VDC for installations where standard voltage is unavailable.

Features

The pump features an enclosed housing and is wall mountable or select from the optional mounting accessories. The Econ T is offered as a Tank System; the pump is shipped pre-mounted to the solution tank. The pump is approved by cULus for indoor and outdoor use and carries NSF 61 and 372. The 25 psi models are tested and certified by Intertek to Standard ANSI/NSF 50, equipment for swimming pools, spas, hot tubs, and other recreational water facilities.

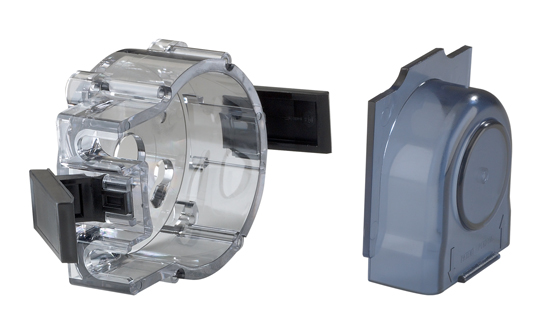

- Tube replacement without tools with patented quick release pump head. VIEW VIDEO

- Solid one piece tube construction.

- Optional mounting accessories available.

Stenner Peristaltic Pump Advantages

- Solution is not in contact with moving parts

- Pump head requires no valves, allows for easy maintenance

- Self-priming against maximum working pressure, foot valve not required

- Pump does not lose prime or vapor lock

- Pumps off-gassing solutions and can run dry

- Output volume is not affected by back pressure

Econ Pump General Installation Video

Econ Pump Tube Replacement Video

Flow Rate Outputs

| Pump Prefix |

Pump Tube | Roller Assembly | Gallons per Day |

Gallons per Hour |

Ounces per Hour |

Ounces per Minute |

Liters per Day |

Liters per Hour |

Milliliters per Hour |

Milliliters per Minute |

|---|---|---|---|---|---|---|---|---|---|---|

| Approximate Output @ 60Hz | ||||||||||

| E10T1A | A | White | 2.5 | 0.10 | 13.2 | 0.22 | 9.5 | 0.39 | 396.0 | 6.60 |

| E10T2A | A | White | 5.0 | 0.21 | 26.4 | 0.44 | 18.9 | 0.79 | 786.0 | 13.10 |

| E10T2B | B | White | 8.5 | 0.35 | 45.6 | 0.76 | 32.2 | 1.34 | 1338.0 | 22.30 |

| E10T2C | C | White | 15.0 | 0.63 | 79.8 | 1.33 | 56.8 | 2.37 | 2364.0 | 39.40 |

| Pump Prefix |

Pump Tube | Roller Assembly | Gallons per Day |

Gallons per Hour |

Ounces per Hour |

Ounces per Minute |

Liters per Day |

Liters per Hour |

Milliliters per Hour |

Milliliters per Minute |

|---|---|---|---|---|---|---|---|---|---|---|

| Approximate Output @ 60Hz | ||||||||||

| E10T1F | F | White | 0.6 | 0.02 | 3.0 | 0.05 | 2.2 | 0.09 | 90.0 | 1.50 |

| E10T2F | F | White | 1.3 | 0.05 | 6.6 | 0.11 | 4.8 | 0.20 | 198.0 | 3.30 |

| E20T4F | F | White | 3.4 | 0.14 | 18.0 | 0.30 | 13.1 | 0.54 | 544.8 | 9.08 |

| E20T4G | G | Black | 12.3 | 0.51 | 65.4 | 1.09 | 46.5 | 1.94 | 1937.4 | 32.29 |

| E20T4H | H | Black | 21.7 | 0.90 | 115.2 | 1.92 | 82.0 | 3.41 | 3416.4 | 56.94 |

Technical Data

| Specifications | |

| Flow Rate Output Control | 24-hr programmable clock; 7 day, 24 event timer |

| Reproducibility | +/- 5% |

| Maximum Working Pressure | 80 psi (5.5 bar), 25 psi (1.7 bar) |

| Maximum Operating Temperature | 104°F (40°C) |

| Maximum Suction Lift | 25 ft (7.6 m) vertical lift, based on water |

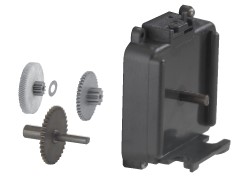

| Motor Type | 24 VDC, brushed |

| Shaft rpm (average maximum) | 9, 18 or 40 |

| Duty Cycle | Continuous |

| Maximum Viscosity | 100 Centipoise |

| Motor Voltage | 120V 60Hz (0.25A), 230V 60Hz (0.17A), 230V 50Hz (10W), 24VDC (0.5A) |

| Power Cord Type | 120V 60Hz, 230V 60Hz: SJTOW, 230V 50Hz: HO5RN-F, 24VDC Pigtail |

| Power Cord Plug End | 120V 60Hz NEMA 5-15P, 230V 60Hz NEMA 6-15P, 230V 50Hz CEE7/7, 24VDC pigtail |

| Power cord Length | 6 ft (1.8m), 10 ft (3.05m) or 24VDC Pigtail 1 ft (30.5cm) |

| Classification | Indoor/Outdoor |

| Materials of Construction | |

| All Housings | Polycarbonate |

| Pump Tube & Check Valve Duckbill | Santoprene®* (FDA approved) |

| Pump Head Rollers | Polyethylene |

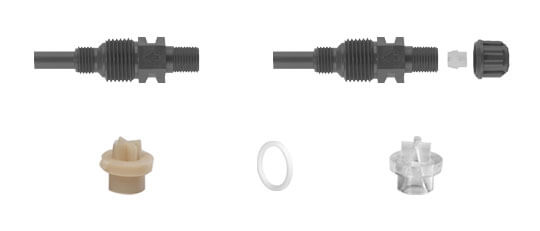

| Suction/Discharge Line, Ferrules | Polyethylene (FDA approved) |

| Tube and Injection Fittings | PVC or Polypropylene (both NSF listed) |

| Connecting Nuts | PVC or Polypropylene (both NSF listed) |

| Suction Line Strainer and Cap | PVC or Polypropylene (both NSF listed); ceramic weight |

| All Fasteners | Stainless Steel |

* Santoprene® is a registered trademark of Celanese International Corporation.

Agency Listings

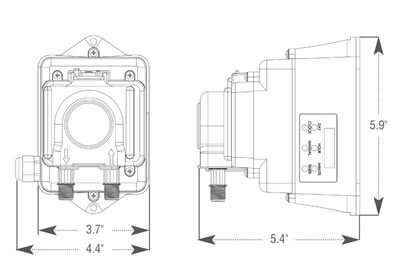

Pump Dimensions

Box Dimensions

8 x 8 x 10 in. (21 x 21 x 25 cm)

Shipping Weight

4 lbs (1.7 kg)