Municipalities and Wastewater Treatment Plants

APPLICATIONS

Well and Surface Water Treatment

Municipalities that supply potable water to residential and commercial sites require treatment of the well or surface water source they use. Well water and surface water need to be disinfected and may need to be treated for problem water issues such as excessive levels of iron, manganese, and hydrogen sulfide which can cause unpleasant odors and staining. In addition, treatment of the return wastewater is required before it can be processed for reuse. Stenner peristaltic metering pumps are used to inject sodium hypochlorite (chlorine) and other related disinfectants.

For odor and stain control, Stenner pumps are also used to meter solutions for oxidation of iron, manganese, and hydrogen sulfide to prevent staining and rotten egg odor. The Econ T pump has an integral timer with 24 event capability with outputs up to 21.7 gallons per day for dosing solutions in lift stations for reduction of odor, fats and oils.

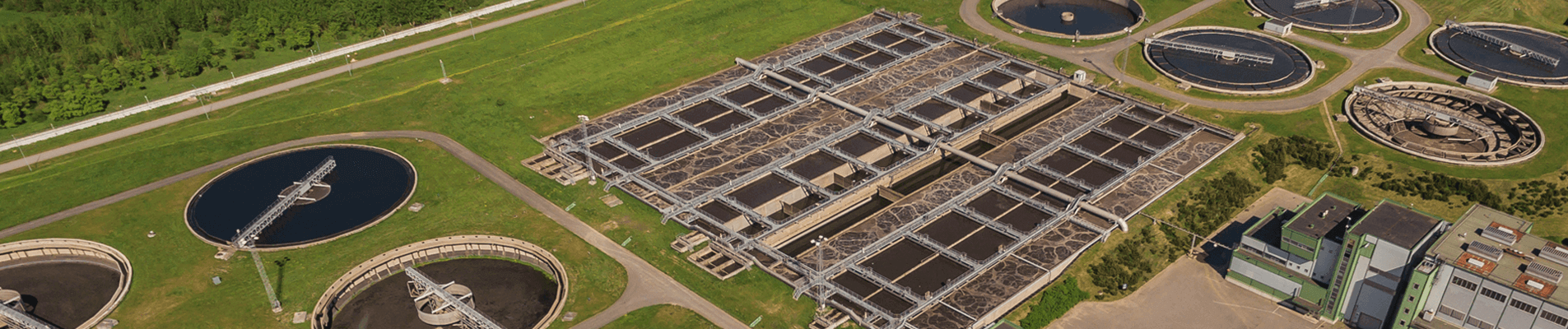

Wastewater Treatment Water reclamation and water reuse provide savings and conservation and may be necessary to comply with environmental regulations. Wastewater is cleaned with biological and chemical treatment for non-potable water. Stenner peristaltic pumps can reliably inject solutions to treat wastewater for reclaimed or recycled use.

pH Adjustment

For both potable and wastewater applications, the effectiveness of key chemicals for disinfection and oxidation is enhanced when the water is in a neutral state. Depending upon the acidic or alkaline condition of the water, Stenner pumps can be employed to meter chemicals to impact the pH level. Pure water is considered to have a pH level of 7. Stenner pumps can meter chemicals such as sodium carbonate or sodium hydroxide to elevate pH or various acids such as phosphoric to reduce the water’s pH level.

Versatile Products for Chemical Injection

Built to NEMA 4X standards, the S Series offers efficient interface with process control systems. Operational modes include scalable, invertible 4-20mA or 0-10VDC input, Hall Effect (frequency), PPM Feed, Pulse and Timer functions. Program up to three output relays to respond to conditions such as tube leak or transfer operation to a backup pump. The pump tube’s life expectancy is programmable to initiate a tube change indicator on the operating display when the set time is reached.

Depending the required flow rate and back pressure requirements, and proportional metering need, Stenner has a complete product lineup to satisfy your demands.