Processing Plants, Commercial Kitchens

APPLICATIONS

Grease Trap Treatment | Drain Field Maintenance

The grease, fats and oils discharged down drains by restaurants, fast food outlets and commercial kitchens cause problems such as clogged drains and plugged drain fields. The septic drain field often collects organic materials along with the grease and fats which can prevent the liquid waste discharge from gradually traveling through the distribution system and into the soil. It is expensive to have the waste product pumped out and/or removed.

A less expensive option is to treat the build-up by injecting a liquid bacteria or enzyme into the drainage system via a metering pump with a timer. Stenner’s Econ T is a compact peristaltic pump with an integral timer programmable to provide an efficient dosage amount and schedule. The pump offers flexibility with 24 separate on-and-off times for a customized dosing schedule. The schedule allows for proper injection rates to be set, so the solutions can do its job.

The Econ TD pump is an extension of the Econ T Series with the programmable 24 hour / 7 day timer. The TD is available as electric or battery-powered and D-limonene can be injected with either model with the FKM tube. The battery powered model also offers a silicone tube option. The Econ T and the Econ TD models include an LCD display with a cover shield and enclosed housing for indoor and outdoor applications.

Equipment Maintenance

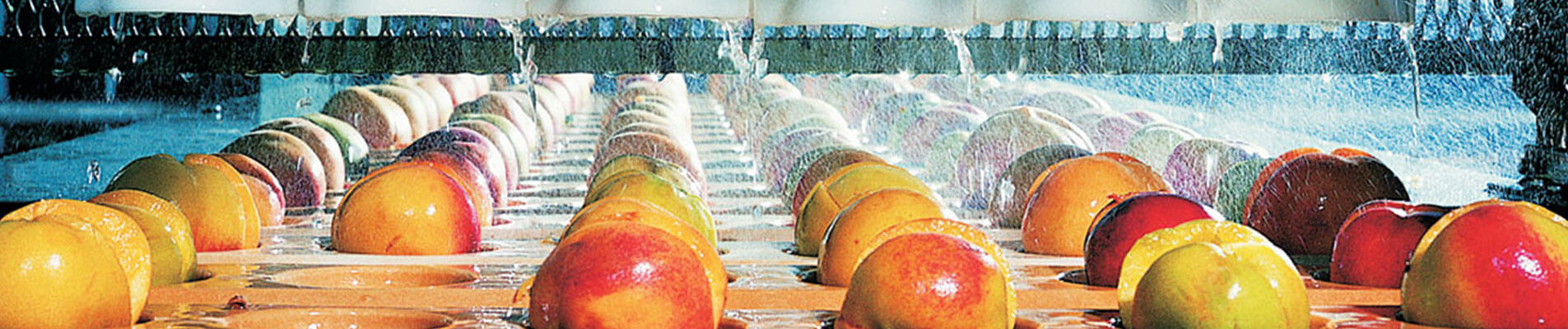

For precise dispensing of lubricants for conveyors, sanitizers or additives, the Econ LD can be set for low volumes for applications requiring less than 50.7 ounces per hour with pressures to 80 psi. The pump utilizes a potentiometer for a turndown ratio of 50:1.

Wastewater Treatment

In some areas, to comply with environmental regulations, the wastewater from the processing method must be treated before discharging it to the drain or septic systems. Often the wastewater needs pH adjustment before it can safely return to the environment.

Additives

The Econ OEM pump can be integrated into a dispensing enclosure for the dispensing of syrups, concentrated juices, and related solutions with outputs up to 4.4 ounces per minute. The Econ OEM batch pump is capable of dispensing food or beverage solutions, and additives in precise amounts based on a pre-set run time from 0.01 seconds to 24 hours per activation. Outputs are available up to 164 ml/min at 25 psi.