Water Treatment on the Farm Without Additional Equipment

Quality water is proven to contribute to the health & production of livestock & poultry and to the maintenance of the water supply equipment. The Integrator is economical; it doesn’t require an additional water meter dedicated to chemical feed for water treatment. The pump is also offered in 24VDC for installations where standard voltage is unavailable.

The Integrator is an efficient, compact pump with cULus for indoor and outdoor use. The “seconds” operational mode is adjustable to accurately inject a fixed amount of chemical per volume of water determined by the pulse rate of the water meter.

A built-in repeater relay provides a dry contact output signal that replicates the same signal the pump receives. The relay feature is especially useful in livestock or poultry operations where an existing dry contact water meter is being utilized to tally water consumption to a controller. Water consumption, a key indicator for animal health is uninterrupted. The relay feature is also perfect for installations requiring multiple pumps, which can be activated by one dry contact pulse water meter.

Water Treatment Applications

- Water and water line disinfection; pH adjustment

- Injection of nutrients and supplements into water lines

- Oxidation of iron, hydrogen sulfide or manganese

- Injection of polyphosphate solutions for corrosion and scale control on plumbing fixtures

Unique Stenner Features

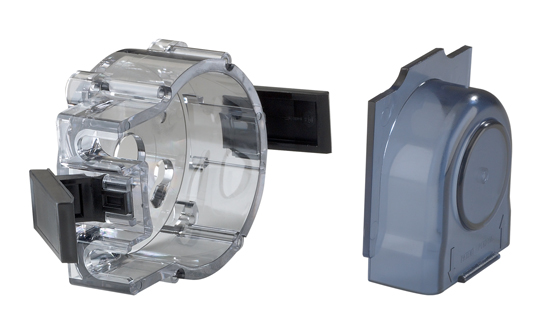

- Patented quick release pump head for periodic tube replacement without tools. VIEW VIDEO

- Inject common undiluted chemicals without harm to the pump; eliminate daily stock solution maintenance.

- Solid one piece pump tube construction.

How It Works

Wire two of the Integrator leads to the water meter, connect another two leads to the house controller, plug the pump into a receptacle and install an injection point in the pipe. The pump is equipped with a safety lockout feature and a standby mode. While in the standby mode the pump is inactive and the relay will continue to register water consumption to the controller when the pump has power applied to it.

The standby mode also allows tube replacement in the pump head without disconnecting power and/or the lead wires. The pump is adjustable from 10% – 100% in 1% increments and is adjusted by a digital keypad with a backlit LCD screen.

Econ Pump General Installation Video

Econ Pump Tube Replacement Video

Flow Rate Outputs

| Pump Prefix |

Pump Tube | Roller Assembly | Gallons per Day |

Gallons per Hour |

Ounces per Hour |

Ounces per Minute |

Liters per Day |

Liters per Hour |

Milliliters per Hour |

Milliliters per Minute |

|---|---|---|---|---|---|---|---|---|---|---|

| Approximate Maximum Output @ 50/60Hz | ||||||||||

| E10RLM | M | White | 0.49 | 0.02 | 2.6 | 0.04 | 1.84 | 0.08 | 76.7 | 1.3 |

| E10RHM | M | White | 0.83 | 0.03 | 4.4 | 0.07 | 3.14 | 0.13 | 130.8 | 2.2 |

| E20RHM | M | White | 1.41 | 0.06 | 7.5 | 0.13 | 5.36 | 0.22 | 223.2 | 3.7 |

| E20RHF | F | White | 4.5 | 0.19 | 24.0 | 0.40 | 17.01 | 0.71 | 708.8 | 11.8 |

| E20RHG | G | Black | 16.0 | 0.67 | 85.3 | 1.42 | 60.48 | 2.52 | 2520.0 | 42.0 |

| E20RHJ | J | Black | 24.0 | 1.00 | 128.0 | 2.13 | 91.00 | 3.79 | 3785.0 | 63.0 |

| E20RHH | H | Black | 30.0 | 1.25 | 160.0 | 2.67 | 113.40 | 4.73 | 4725.0 | 78.8 |

Technical Data

| Specifications | |

| Flow Rate Output Control | Six button control panel with LCD display |

| Reproducibility | +/- 2% |

| Maximum Working Pressure | 80 psi (5.5 bar) |

| Maximum Operating Temperature | 104°F (40°C) |

| Maximum Suction Lift | 25 ft (7.6 m) vertical lift, based on water |

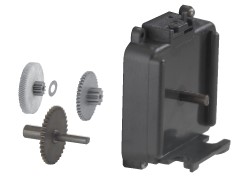

| Motor Type | 24 VDC, brushless |

| Shaft rpm (average maximum) | 60 |

| Duty Cycle | Continuous |

| Motor Voltage | 120V 60Hz (0.25A), 230V 60Hz (0.17A), 24VDC (0.85A) |

| Power Cord Type | 120V 60Hz, 230v 60Hz: SJTOW, 24VDC pigtail |

| Power Cord Plug End | 120V 60Hz NEMA 5-15P, 230V 60Hz NEMA 6-15P, 24VDC pigtail |

| Power Cord Length | 6 ft (1.8 m), 10 ft (3.05 m) or 24VDC Pigtail 1 ft (30.5 cm) |

| Classification | Indoor / outdoor |

| Materials of Construction | |

| All Housings | Polycarbonate |

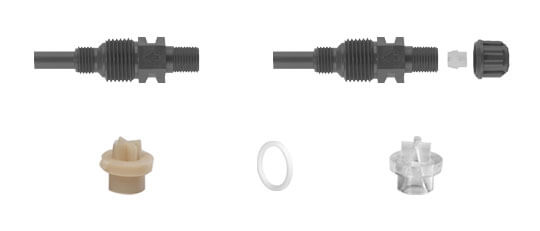

| Pump Tube & Check Valve Duckbill |

Santoprene®* (FDA approved) |

| Pump Head Rollers | Polyethylene |

| Suction/Discharge Line, Ferrules | Polyethylene (FDA approved) |

| Tube and Injection Fittings | PVC or Polypropylene (both NSF listed) |

| Connecting Nuts | PVC or Polypropylene (both NSF listed) |

| Suction Line Strainer and Cap | PVC or Polypropylene (both NSF listed); ceramic weight |

| All Fasteners | Stainless steel |

* Santoprene® is a registered trademark of Celanese International Corporation.

Agency Listings

Listings vary by model.

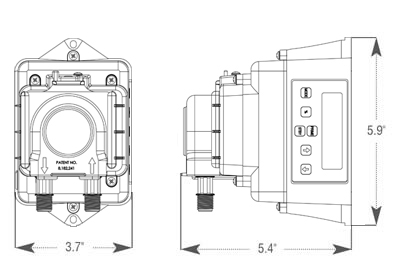

Pump Dimensions

Shipping Weight

4 lbs (1.8 kg)

Box Dimensions

8 x 8 x 10 in. (21 x 21 x 25 cm)